The secrets behind efficient aluminum casting and foundry operations

Wiki Article

Recognizing the Relevance of Aluminum Casting in Modern Production Processes

Light weight aluminum spreading has become an essential part in modern production. Its light-weight and resilient nature adds substantially to different industries, from auto to electronics. Furthermore, improvements in casting techniques improve manufacturing effectiveness and high quality. As producers seek innovative solutions, the role of light weight aluminum casting in sustainability becomes significantly pertinent. This discussion will certainly explore the multifaceted relevance of aluminum spreading and its effects for the future of production. What lies ahead in this progressing landscape?The Advantages of Light Weight Aluminum Casting in Manufacturing

Aluminum casting offers numerous advantages that boost its charm in modern-day manufacturing processes. One major benefit is its light-weight nature, which leads to minimized energy intake and boosted fuel effectiveness in transportation applications. Furthermore, aluminum's excellent corrosion resistance prolongs the life-span of cast items, making them extra sturdy in numerous environments. The product likewise promotes complex designs and intricate geometries, allowing producers to create components that fulfill exact specifications.In enhancement, aluminum casting boasts a fairly reduced melting point, which saves power throughout the production procedure. This attribute likewise enables fast cycle times, raising total performance. The recyclability of aluminum contributes to sustainability efforts, as recycled aluminum calls for substantially less power to process compared to primary aluminum. Jointly, these benefits placement light weight aluminum casting as a necessary strategy in modern manufacturing, accommodating the needs for performance, performance, and ecological responsibility.

Applications of Aluminum Spreading Across Industries

While numerous materials are used in production, aluminum casting has actually ended up being a critical approach across several industries as a result of its adaptability and functionality. This process is widely used in the vehicle sector for producing light-weight engine blocks, transmission instances, and various parts that enhance fuel effectiveness. In the aerospace industry, aluminum spreading is important for developing detailed parts that require high strength-to-weight ratios, adding to boosted aircraft efficiency.The electronics industry relies on light weight aluminum castings for warm sinks and real estates, where thermal monitoring is vital for gadget long life. The building market likewise gains from aluminum casting in the form of architectural elements and structural elements that combine aesthetic allure with sturdiness. In addition, the customer goods market makes use of light weight aluminum castings for cookware and showing off equipment, leveraging the product's outstanding deterioration resistance and visual finish. On the whole, aluminum spreading acts as a foundation in modern manufacturing, supporting varied applications throughout numerous areas.

The Duty of Light Weight Aluminum Spreading in Sustainability

Sustainability has actually ended up being a centerpiece in producing methods, and aluminum casting plays an essential function in advertising eco-friendly remedies. The process of aluminum casting is inherently sustainable as a result of the product's recyclability. Light weight aluminum can be recycled several times without losing its residential or commercial properties, greatly reducing power intake and basic material needs. This reusing procedure consumes just around 5% of the energy needed for key aluminum manufacturing, causing a noteworthy reduction in carbon discharges.Aluminum casting promotes the manufacturing of lightweight parts, which contribute to energy performance in different applications, especially in the automotive and aerospace sectors - Precision aluminum casting. Lighter vehicles consume much less fuel, more reducing ecological impact. Additionally, developments in casting techniques are maximizing material use, reducing waste in producing procedures. As industries seek to straighten with sustainability goals, light weight aluminum casting becomes a sensible remedy, sustaining a round economic situation and promoting accountable production techniques

Technological Developments in Light Weight Aluminum Casting Techniques

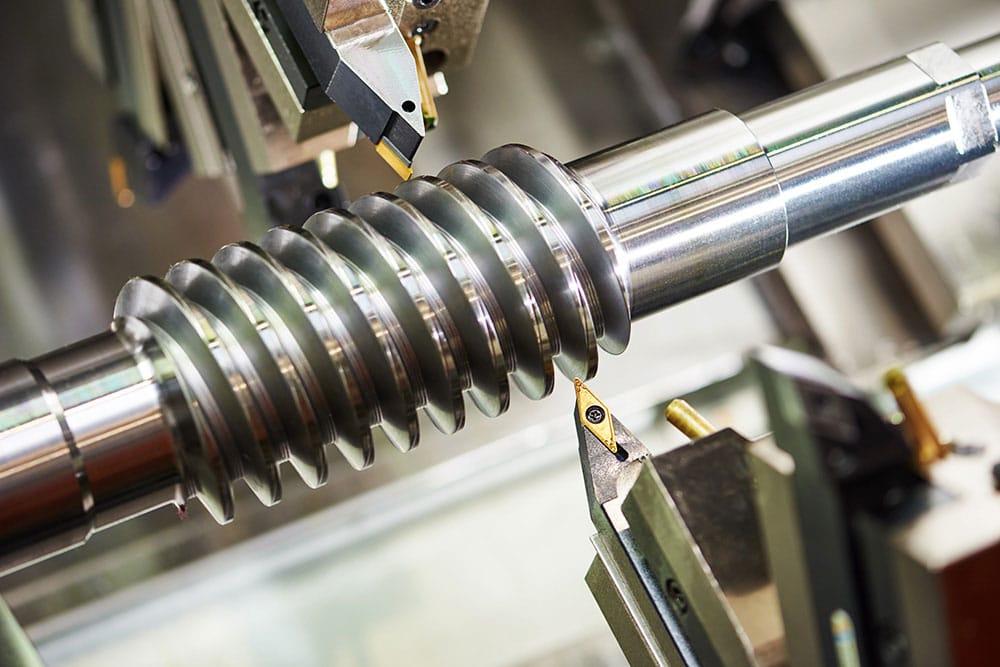

As markets evolve, the fostering of cutting-edge technologies in aluminum casting strategies has actually changed producing processes. The assimilation of computer-aided layout (CAD) and computer-aided manufacturing (WEB CAM) systems improves precision and effectiveness, permitting complicated geometries that were formerly testing to produce. Advanced melting and casting approaches, such as die spreading and investment spreading, have boosted the high quality of light weight aluminum components, reducing flaws and Home Page decreasing waste. The introduction of automated systems and robotics in casting procedures has structured operations and boosted productivity. These innovations also allow real-time monitoring and data analytics, promoting much better decision-making and quality assurance. In addition, the development of brand-new alloys and warmth therapy procedures has actually expanded the performance capabilities of actors aluminum products. Collectively, these technical advancements not only maximize manufacturing effectiveness however also add to the sustainability of light weight aluminum casting in modern-day production.Future Fads in Light Weight Aluminum Spreading and Its Effect On Technology

Emerging trends in light weight aluminum spreading are positioned to reshape the production landscape, driving development throughout different markets. One significant fad is the integration of innovative automation and robotics, which improves precision and efficiency in production procedures. In addition, the rise of additive manufacturing methods is permitting more complex designs, lowering material waste and manufacturing time. As sustainability ends up being a concern, the industry's focus on recycling light weight aluminum and using green techniques is anticipated to expand, straightening with international ecological objectives.Furthermore, the advancement of wise spreading modern technologies, including real-time tracking and information analytics, is readied to boost top quality control and functional effectiveness. These advancements will certainly facilitate the manufacturing of lighter, stronger, and more durable aluminum components, satisfying markets such as automotive and aerospace. Inevitably, these trends will not only optimize producing procedures but additionally motivate brand-new applications of light weight aluminum casting, promoting a culture of innovation and flexibility on the market.

Frequently Asked Inquiries

What Is the Background of Aluminum Spreading in Production?

Just How Does Aluminum Spreading Contrast to Other Metals?

Aluminum casting deals advantages such as lightweight residential properties and corrosion resistance contrasted to various other steels. Precision aluminum casting. It assists in intricate shapes and enhances power efficiency, making it a favored selection in different manufacturing applications over much heavier alternatives like steel or ironWhat Are the Typical Defects in Light Weight Aluminum Spreading?

Typical defects in light weight aluminum casting include porosity, shrinkage, misruns, and inclusions. These issues can arise from improper putting techniques, insufficient mold and mildew design, or polluted materials, causing decreased architectural integrity and performance of the end product.How Is the Top Quality of Aluminum Castings Tested?

The high quality discover this info here of aluminum spreadings is examined via techniques such as aesthetic inspections, dimensional dimensions, non-destructive testing strategies, and mechanical property assessments, making sure that they fulfill specified go to this website standards for performance and architectural honesty.

What Are the Precaution in Aluminum Casting Processes?

Safety and security procedures in light weight aluminum spreading procedures include using personal protective tools, correct ventilation systems, regular devices upkeep, training workers on threats, and executing rigorous emergency methods to decrease threats connected with high temperature levels and liquified steel.The recyclability of light weight aluminum adds to sustainability initiatives, as recycled aluminum calls for considerably less power to procedure compared to main aluminum. While different products are employed in production, aluminum spreading has actually become an essential technique across several industries due to its flexibility and functionality. Advanced melting and casting techniques, such as die casting and financial investment casting, have actually improved the high quality of light weight aluminum components, decreasing issues and minimizing waste. Arising trends in light weight aluminum spreading are poised to reshape the production landscape, driving innovation throughout numerous industries. Light weight aluminum casting has actually evolved since the late 19th century, originally establishing with the intro of aluminum as a lightweight steel.

Report this wiki page